Cemex

Building a connected quarry model to transform operations

Cemex, a global leader in the aggregates sector, is pursuing digital transformation with a focus on both internal and external operations. In 2017, they launched CEMEX Go, a digital platform that automates customer interactions, from ordering to delivery tracking. Internally, they have adopted a "connected quarry" model to optimize truck and machine efficiency using telematics data. To support these goals, Cemex has partnered with Alteia to centralize topographic and machine data, utilizing the platform's data analysis and AI capabilities to drive their digital initiatives.

We’ve chosen Aether by Alteia to be the central hub of our topographic data to not only centralize our initiatives related to this ambitious and transformational strategic project, but also to leverage big data analysis and AI capabilities of the platform.

Benjamin LecendrierDirector of Operations for Aggregates

Accelerating and streamlining inventory management

Leverage image segmentation and calculation tools to create automated inventory reports and compare production from month to month to assess production variability.

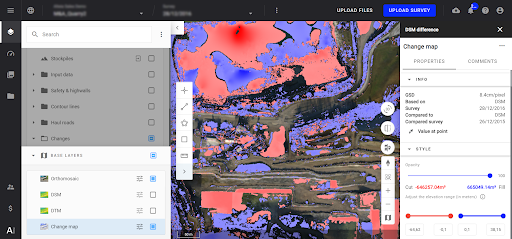

Assess changes over time leveraging data contextualization and change algorithms

View and compare site conditions to estimate production or evaluate blast efficiency. Monitor excavation progress to keep your team informed and ensure the production schedule stays on track.