Eramet

Digitizing mining operations to increase operational performance

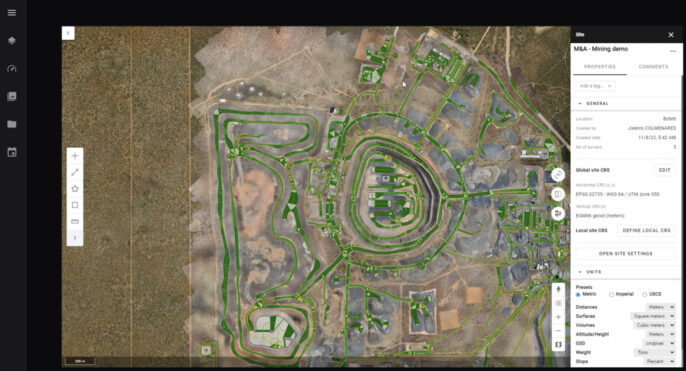

Eramet, a global mining and metallurgy group, needed a platform to store, analyze, and visualize data from its 47 mining sites. Recognizing the benefits of digital twins for safety and productivity, they faced challenges in creating digital records from diverse data sources. With Alteia's platform, Eramet now seamlessly integrates visual intelligence, providing instant access to digital twins of all sites.

The collection of images by different means and the storage and processing of the images on the Alteia platform allows to assess quickly the impact of the mine on the environment and to verify that it is as low as possible.

Jean Loup LoyerChief Data & Analytics Officer

Site reconciliation

Quantify site differences month-on-month, assess deviations from pit design, measure volume remaining to final pit limits, and identify change in vegetation nearby the site

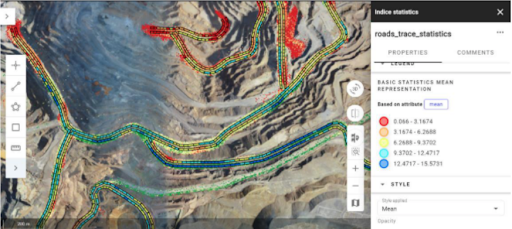

Ensure haul road safety and compliance with AI

Automatically detect grade, width, crossfalls, berm heights and more.

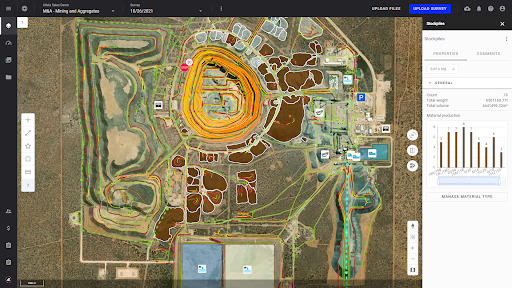

Integrate machine data to cut maintenance costs

The software overlays telematic data from trucks, with sensors on the vehicles sending alerts when certain parts experience stress. The resulting map highlights areas where road maintenance could help alleviate stress on trucks, thereby reducing maintenance costs.

Run simulations to improve truck path and optimize fuel consumption

Analyze haul truck trajectories, speed, and real-time fuel consumption to evaluate the optimization of haul road geometry.