Vision AI for solar farm lifecycle management

Solar PV generation increased by a record 200 TWh (up 22%) in 2022 to exceed 1 000 TWh. It demonstrated the second largest absolute generation growth of all renewable technologies in 2022, after wind.

Solar PV is becoming the lowest-cost option for new electricity generation in most of the world, which is expected to propel new investments in the coming years.

By the way an averaged annual generation growth of 25% in the period 2022-2030 is needed to follow the Net Zero Emissions scenario by 2050. This represents a more than threefold increase in annual capacity additions by 2030, requiring new construction projects, additional policy work, and tighter integration with the grid.

With the pressure to deliver more energy faster, infrastructure funds, site operators and contractors want to ensure more than ever that everything is on track during the construction phase as more and more projects are coming to life. As such they have started monitoring construction projects closely. However, monitoring the construction of solar farms and inspecting them during production can be a daunting task, especially since they cover such large areas in often remote locations.

Traditional methods of monitoring and inspection are time-consuming and expensive, especially in the context of a growing portfolio of operations, so the use of visual imagery from satellites, drones, or ground cameras is becoming increasingly popular.

This data can be analyzed using the Alteia worksite management application to identify changes over time, track the progress of solar projects, document the commissioning process, or monitor the health of solar panels during production.

In this article, you’ll learn about Alteia’s worksite management application and how it can become a critical component of asset management for renewable energy resources, and an important source of collaboration at different phases of a solar project : site preparation, construction progress monitoring and post-commissioning lifecycle management.

Site preparation

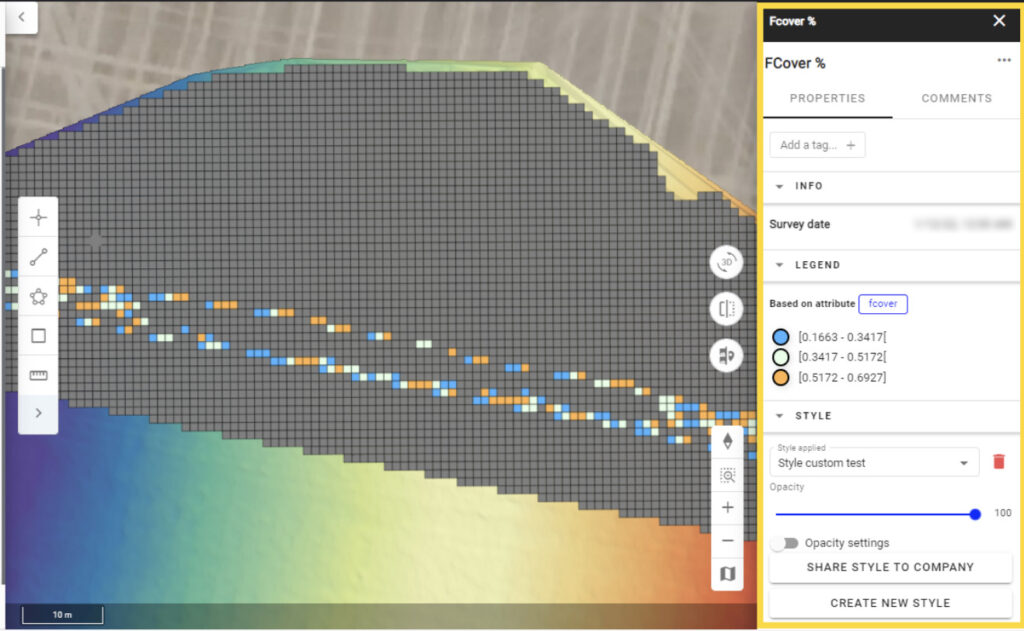

When starting a solar farm construction project, it is important to consider the site preparation that will be required. The first step in any site preparation is site clearing. Site clearing is the process of removing all trees, vegetation, debris, and other obstructions from the site. This is usually done with heavy equipment such as bulldozers and excavators. Leveraging the worksite management application and included vegetation analytics (like FCover) it is easy to export vector files of where the vegetation is and get an assessment of what work needs to be done and what plan needs to be put in place. It is also easy to calculate how many trees need to be replanted (based on how many have been removed) and therefore document compliance with ESG targets.

FCover calculation for site clearing assessment

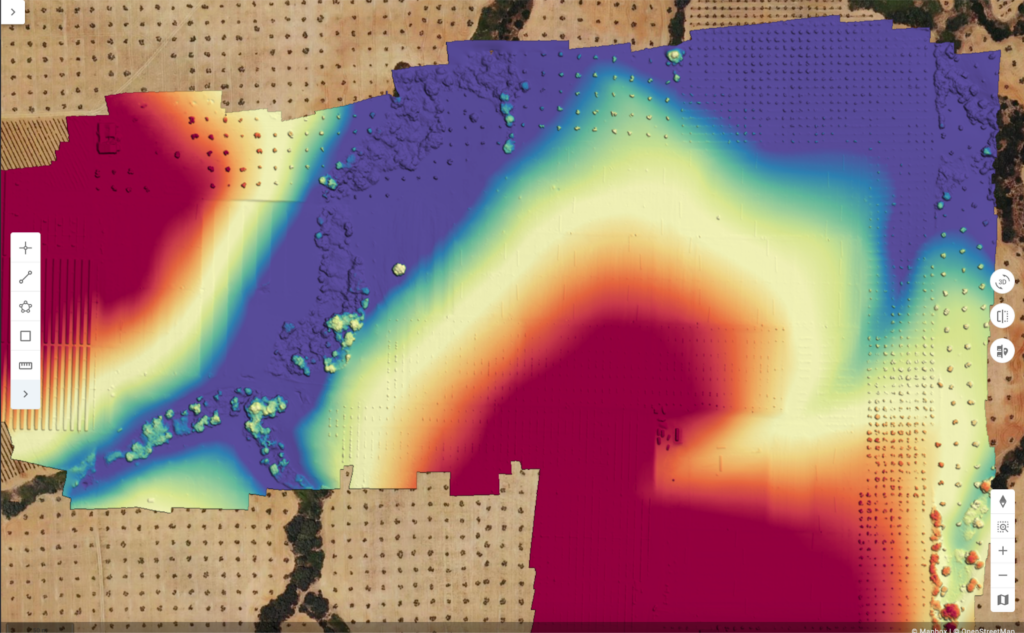

The second step is site surveying. In this step, the construction team surveys the land to determine the best way to lay out the site. Site surveying is an essential step because it is required for zoning and permitting processes, including determining the boundaries of the site, where to place solar panels and other structures, and how best to connect utilities.

Our integrated digital topographic tools allow engineers and surveyors to share and analyze highly accurate topographic maps derived from visual data to identify elevation changes, slopes, and other terrain features.

DSM visualization of a site

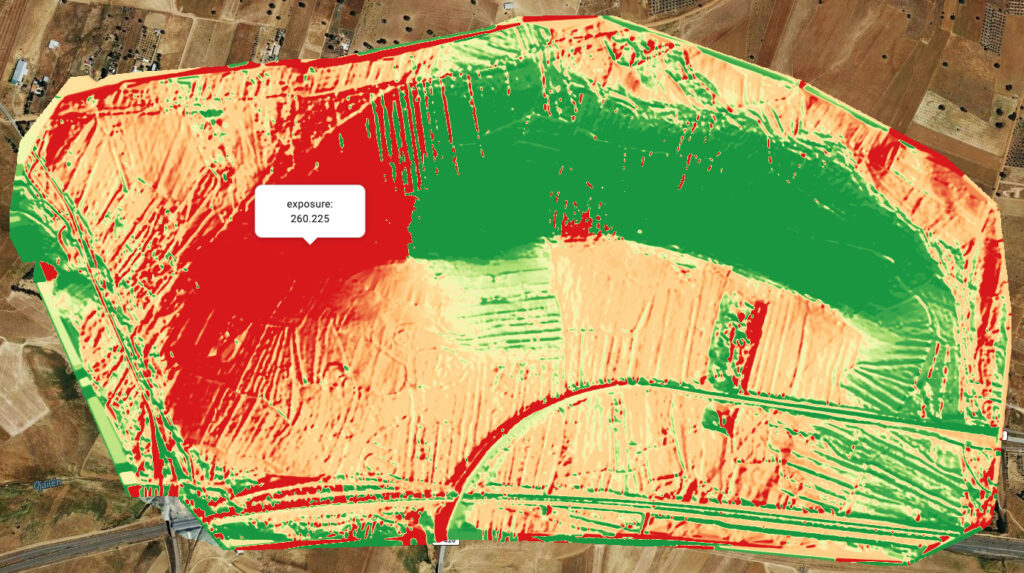

This information can also be used to plan the placement of structures and infrastructure based on sun exposure, as well as making sure the site is in full compliance from a zoning perspective. it is also possible to overlay the design files for all utilities, and assess any potential mistake or conflict.

Sun exposure assessment of a site – courtesy of Optim.aize

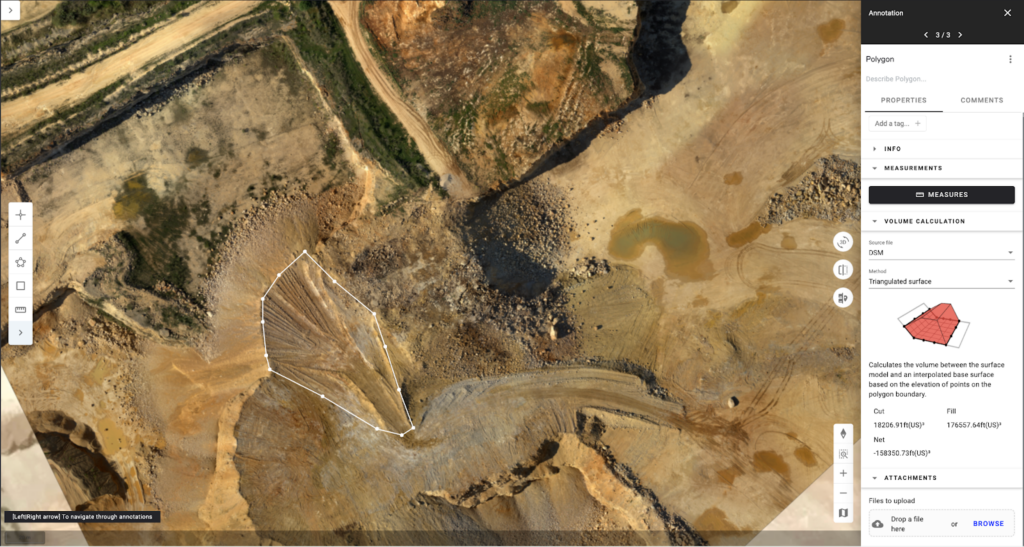

Finally, by using drones to capture images of excavation sites and stockpiles, construction managers can calculate the amount of material moved and track progress over time. This data can be used to optimize excavation and grading operations, as well as to verify quantities for billing purposes.

Volumetric estimation of a stockpile

Solar farm construction monitoring

When it comes to tracking progress, satellite imagery and drones can provide an overview of the entire solar farm, giving project managers a bird’s eye view of construction progress. By combining such visual data with machine learning workflows, site managers can analyze and identify any delays or gaps and ensure that construction is on track.

As an example, data provided by drones and combined with AI can be used to monitor the installation of solar racks and support structures to ensure they are installed correctly and to the required specifications. They can also be used to monitor the condition of access roads, perimeter fences, and other critical components.

In addition, visual data can be used to identify potential problems with the site, such as soil erosion, waterlogging, or other environmental concerns.

Now, let’s take a closer look at how Alteia’s worksite management application helps site managers monitor construction work over a solar farm.

We use different AI workflows to do this.

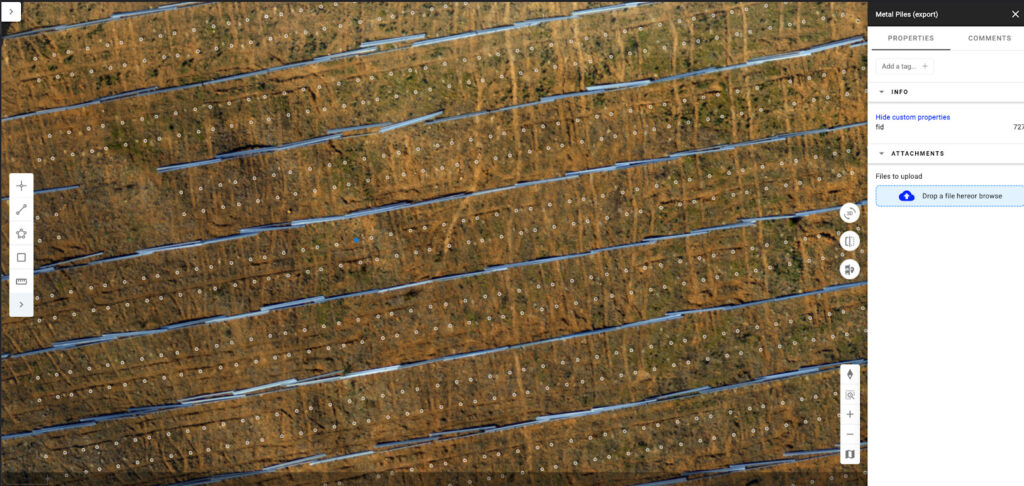

For example, we use automated object detection to detect holes in the ground that serve to mount the metal piles. It helps detect early equipment placement and orientation issues.

Automated detection of holes in the ground using AI

About solar panels, AI can be trained to detect them and monitor their installation progress compared to the design files. It help ensuring that all panels are installed correctly and are facing the right direction for maximum energy production.

Automated detection of solar panels and comparison to design

To monitor the installation progress specifically, we use the “change map”.

Progress monitoring via change map

This allows us to compare two different DSMs from one day to another and immediately see what has changed. When viewing the change maps, you can easily see the frames, but also the range of panels that have been installed between two surveys. The combination of change maps and comparison tools makes it easy to track progress.

At any time, you can navigate through all your data and share it with all project stakeholders, then organize the set of actions to be taken and assign them to the relevant teams.

Maintenance operations

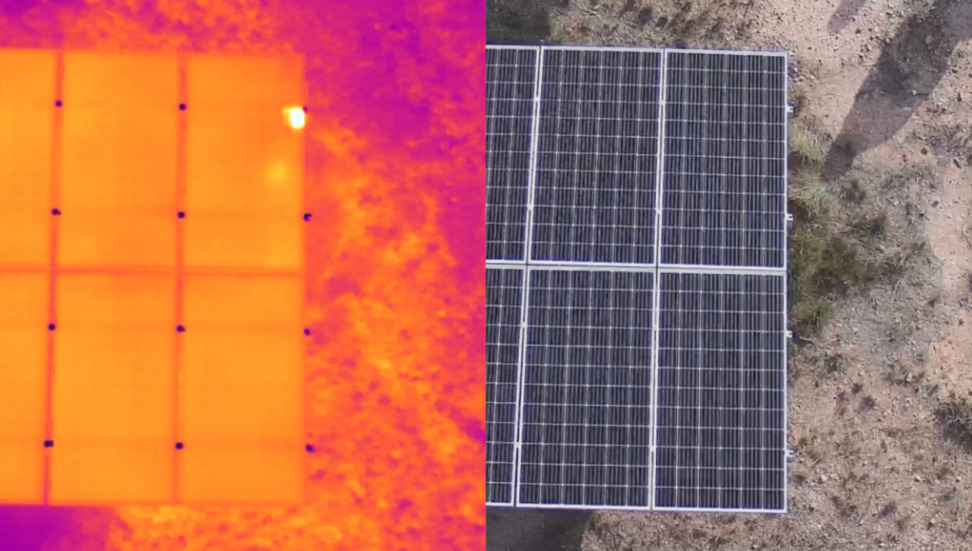

Once a solar farm is up and running, it is important to ensure that the solar panels are working efficiently. Vision AI can be a very effective tool for site managers to do this, especially in understanding why production is not as high as expected.

Manual inspection of each panel across such a large space would require a prohibitive amount of effort. Aerial drones equipped with infrared or electroluminescence cameras can cut inspection time in half. Electroluminescence imaging looks for defects within a PV module such as cracks, short-circuited cells, shunts or layer defects.

Using Alteia’s site management application, site managers can digitally inspect the condition of the panels and identify any damage, cracks, or other issues that may affect their performance. AI can identify issues such as improperly installed equipment, damage to solar panels, or other issues that may require attention. In addition, drones can be used to inspect wiring and connectors to ensure they are properly connected and functioning properly.

The greatest advantage of aerial inspections is its speed. On average, drones are able to collect data 70% faster than manual methods while having 99% accuracy.

This increased speed even more and allows for a total inspection of a site to be completed in a much shorter time frame and ensures that every module has been accounted for.

Malfunctioning modules, strings, combiners, or inverters that may not have been detected using traditional inspection methods can be quickly identified and repaired, increasing overall site yield.

One solar asset owner estimates that they save $383,127 annually by repairing defective modules that likely would not have been discovered during on-foot inspections.

AI can also analyze images of solar farms to detect safety hazards to ensure security on site or environmental factors that could affect energy production, such as shading from trees or buildings. This can help construction companies and solar farm operators make adjustments to equipment placement or orientation to maximize production.

Such digital inspection workflow adds strong benefits in the following 4 key areas:

- OpEx efficiency : Frequent aerial inspections allows solar farm operators to direct their team to the right place at the right time, detect early-stage faults and improve preventive maintenance.

- Scaled-up : Swapping time-consuming manual inspections for autonomous ones is key to knowing what is going on with solar farms that extend beyond the reach of human sight.

- Higher yields : Thermal, comprehensive PV inspections using drones means that anomalies like an offline string, diode anomaly, or tilted tracker, are caught quickly. Timely spotting of problems empowers timely fixes, minimizing impact on energy production.

- Warranty enforcement : Anomaly data is automatically recorded, providing the documentation needed for successful warranty and insurance claims. The site manager can keep an archive of everything that happened during the construction phase. If a problem arises during operations, he can always go back to that archive file. In this way, AI helps site managers save time and improve maintenance efficiency.

Conclusion

The use of visual data combined with AI can be a valuable tool for site preparation and project monitoring of solar farm projects. By using visual data, project and site managers can better budget and ensure that construction is on track.

Vision AI and drone inspection workflows can also be a very scalable solution for intelligent solar panel inspection, ensuring the solar panels are working the way they should in the production phase and stay free from defects or cracks.

Thanks to cloud computing platforms and automated workflows like Alteia worksite management application, you can:

- Streamline your data flow

- Get reliable results and reports in minutes

- Have all stakeholders collaborate from a single source of truth

- Keep highly accurate data of your site at every moment, which is highly beneficial if any issue arises.

Click here to know more about our Worksite Management App.